Product

We know your needs

Advantage

- Light structure, easy installation and maintenance

- Widely used in different places for hoisting such as factories, warehouses and material yards;

- Reasonable structure, strong bearing capacity

- Low noise, soft starting and stopping

- Safe and reliable operation

- Low cost maintenance, long working life

- Heavy duty Sq. cage motor with VVVFD, IP54 or IP44,insulation class F or H

- Standard Make main electric parts are used for durable and safe operation.

- Prohibited to use in the environment with inflammable, explosive and corrosive media

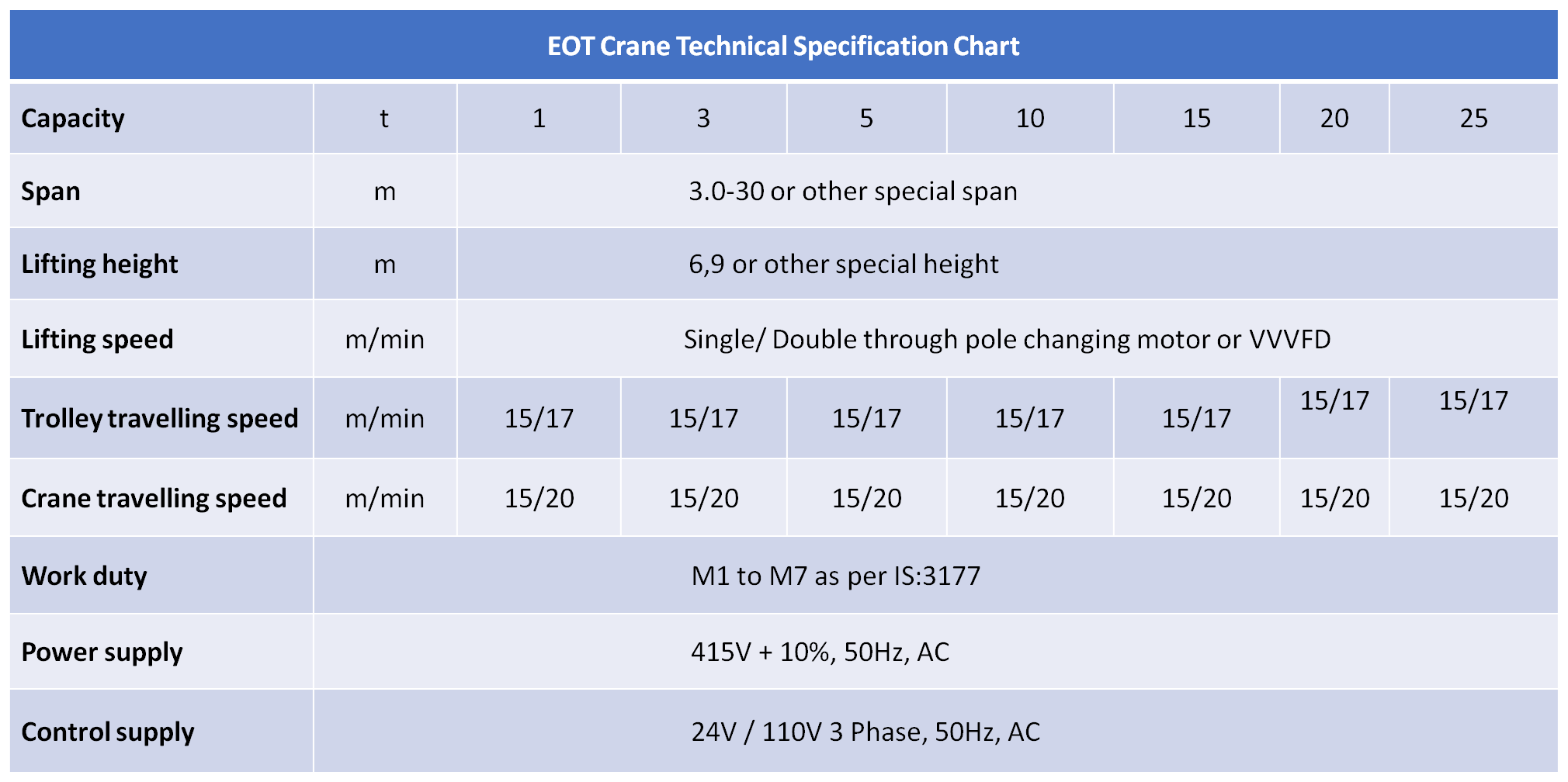

Technical Information

- Lifting Capacity: 1~25t

- Span Length: 3.0~25.0m

- Lifting Height: 6~21m

- Lifting Speed: 0.3-8m/min

- Working Class: M1-M7

- Ambient Temperature: -20~50℃

- Rigid box-typed/ customized beam/ standard beam main girder

- Referring IS:807 & IS:3177 standard

- Shot blasting for the whole body after welding and releasing internal stresses.

- Main girder and end carriages are connected by 10.9 grade high-strength bolts.

- Driven by electric geared motor

- Running smoothly, brake efficiently, long service life

Description

What is the advantage of EOT Crane?

- EOT crane can provide three axis of hook motion and cover a large rectangle area. The area can increase by prolong the length of end trucks.

- Installed in the upper part of the plant, it take little floor space. The possibility that need of forklifts and meet obstacle is reduced. This in turn improve the safety and efficient.

- It is typically adapted to harsh and heavy load environments, such as steel industry, the paper industry, power generation and refineries.

- With the favorable structure, EOT crane need less maintenance compared to other kind of lifting equipment. It is more cost effective.

EOT crane is a kind of crane traveling along two parallel rails and lifting mechanisms travel along horizontal main girder. Indian standard EOT crane is composed of main girder, end girders, traveling mechanisms, lifting mechanism (hoist) and electrical components. This crane is usually used in long distance workshops and runs along the rails on both sidewalls. ... more

Accessories

Dual Speed:- The more cost-effective option is to have a single speed but most users prefer to have the option of dual speed control on all motion functions. This enables a slow speed for creeping a load in to place as well as a fast speed for normal operation.

Limit Switches:- Offered as standard on all motions and optional on hoisting upper and lower limit

Radio Remote Controls:- As an alternative to a wired pendant control, buyers of Electric Hoists are able to specify a radio control system which enables the user to stand at a safe, remote distance from the load, this has many added advantages such as the operator being able to see from a better angle of the load, he also remains a safer distance from the load and has better flexibility when operating the hoist in general.

There are numerous benefits of using a VFD to control a hoist or crane, including:

GREATER SPEED ADJUSTMENT:- VFD controls let you choose from multiple speeds, allowing you to customize your hoist speeds to your application.

IMPROVED LOAD CONTROL:- Positioning a load using a single-speed hoist may cause shock loading or load swings. Two-speed may not give you the desired range of speeds for sensitive positioning because they typically are offered in 3 to 1 or 5 to 1 speed range. A VFD allows for smooth operation by gradually slowing down a load and offers speed ranges of 100 to 1 or more in many applications. Retrofits of existing cranes and hoists easily allow for 10 to 1 speed range. VFDs also allow for smooth acceleration to prevent load swings in the traverse motions.

DUTY CYCLES:- CMAA Class A-F. A VFD is c matched with a braking resistor, depending on the duty cycle of the motion. A regenerative drive may also be used, which is not dependent on duty cycle.

EFFICIENCY:- A VFD will only consume the power that’s needed, thus saving energy compared to contactors and soft-starters.

INCREASED HOIST LIFE:- Some variable frequency drives provide thermal overload and over current protection for the hoist motor, prolonging its life. VFDs also utilize a ramp-down-to-stop method of braking rather than using brake shoes to slow down. The brake is only used for parking and emergency situations, which greatly increases brake life while reducing the need for maintenance and adjustments. VFD’s eliminate the need for reversing contactors (another maintenance and repair item) for motion and speed control